Key points of screw conveyor selection

2019-06-04

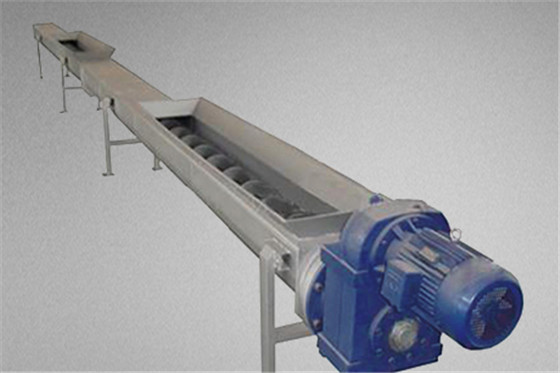

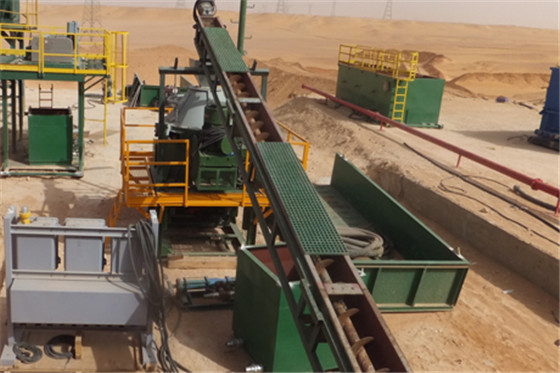

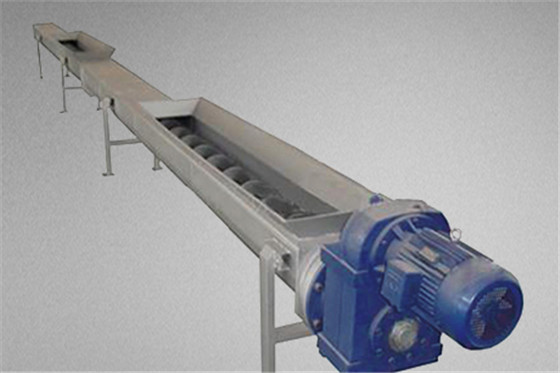

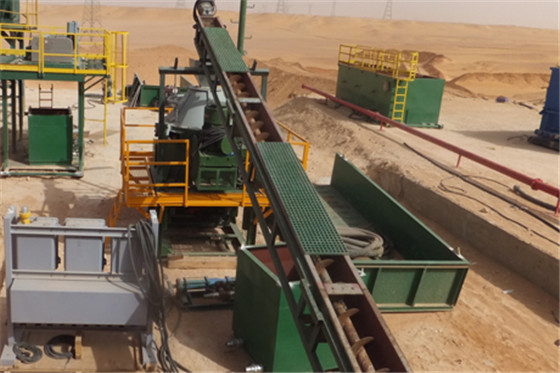

Conveying capacity: conveying capacity of screw conveyor refers to the amount of materials transported per unit time. When conveying bulk materials, calculate the mass or volume of materials transported per hour; The number of pieces per hour shall be counted when the goods are transported. In support of various types of vibrating screen equipment, to extreme vibration screen feed amount, control the throughput. Most of the conveyor before the design and production will consider whether to use with other production equipment, in order to design a reasonable model of the conveyor.

Conveying speed: increasing the conveying speed can improve the ability of human health. When the screw conveyor belt is used as the traction part and the conveying length is large, the conveying speed increases gradually. But high speed running belt conveyor should pay attention to vibration, noise and start, brake and other issues. For the chain as a traction part of the screw conveyor, the transmission speed should not be too large, to prevent the increase of dynamic load. At the same time for the process control of the feeder, the transfer speed should be determined according to the production process requirements.

Component size: the component size of the conveyor includes belt width, slab-width, hopper volume, pipe diameter and container size, etc. The dimensions of these components directly affect the conveying capacity of screw conveyor.

Conveying length and inclination Angle: the length and inclination Angle of conveying line directly affect the total resistance and required power of the conveyor. Now there are many types of conveyor, there are direct parallel feeding, some with a certain inclination Angle, so when the screw conveyor selection to explain these operating conditions.

Screw conveyor motor can choose adjustable speed motor and ordinary motor, control the transmission speed and per hour of the conveyor. Whether a hopper is added at the feed port, and the size of the feed port.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng

http://www.kosun.com

http://www.kosuneco.com

Conveying speed: increasing the conveying speed can improve the ability of human health. When the screw conveyor belt is used as the traction part and the conveying length is large, the conveying speed increases gradually. But high speed running belt conveyor should pay attention to vibration, noise and start, brake and other issues. For the chain as a traction part of the screw conveyor, the transmission speed should not be too large, to prevent the increase of dynamic load. At the same time for the process control of the feeder, the transfer speed should be determined according to the production process requirements.

Component size: the component size of the conveyor includes belt width, slab-width, hopper volume, pipe diameter and container size, etc. The dimensions of these components directly affect the conveying capacity of screw conveyor.

Conveying length and inclination Angle: the length and inclination Angle of conveying line directly affect the total resistance and required power of the conveyor. Now there are many types of conveyor, there are direct parallel feeding, some with a certain inclination Angle, so when the screw conveyor selection to explain these operating conditions.

Screw conveyor motor can choose adjustable speed motor and ordinary motor, control the transmission speed and per hour of the conveyor. Whether a hopper is added at the feed port, and the size of the feed port.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng

http://www.kosun.com

http://www.kosuneco.com

News

- 07-11Technical features of using KOSUN drilling waste mud treatment system

- 07-07Main equipment of solids control system in drilling

- 06-26Geothermal well mud treatment system manufacturer—KOSUN solid control

- 06-26The key to achieving mud zero discharge is on-site processing after solid-liquid separation

- 05-10Application Scenarios of KOSUN Drilling Waste Treatment Equipment

- 05-10Environmental protection new regulations require to achieve zero discharge of drilling waste

- 05-09KOSUN Solid-liquid Separation Equipment is used in the construction industry

- 04-19What are the main functions of the Mud Agitator during use?

- 04-15The Advantages of KOSUN's trenchless horizontal directional crossing mud recovery system

- 03-15Vacuum degasser is mainly divided into centrifugal degasser and jet degasser